Product Description

The 10T, 3/4" Bore Centrifugal Clutch, #41 - Heavy Duty is a top-of-the-line clutch designed for use in heavy-duty applications. This clutch features a 10-tooth sprocket and a 3/4" bore, making it compatible with a wide range of engines. It is made from high-quality materials and is built to last, even in harsh conditions. The heavy-duty construction of this clutch ensures reliable and consistent performance, even under the most demanding circumstances. It is easy to install and comes with all the necessary hardware for a hassle-free installation. This clutch is designed to provide optimal power transfer from the engine to the transmission, ensuring smooth and efficient operation. Whether you're using it for racing, off-roading, or other heavy-duty applications, the 10T, 3/4" Bore Centrifugal Clutch, #41 - Heavy Duty is a great choice for anyone looking for a high-quality, reliable, and durable clutch.

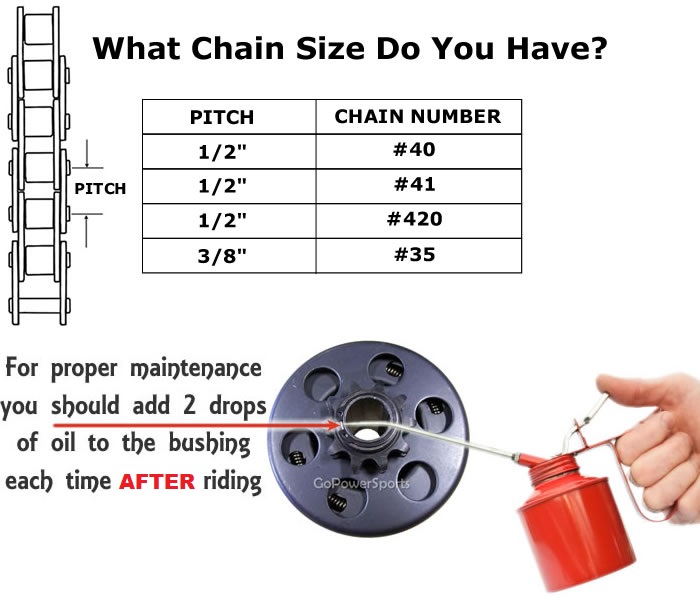

Heavy duty centrifugal clutch, 3/4" bore, 10 tooth, #41/420 chain. This fits on a 3/4 crankshaft. The end of the crankshaft must be drilled and tapped to accept a bolt to hold clutch onto shaft. Comes with 3/16" key. This is a heavy duty clutch designed for standard live axle karts using up to 14" tall tires. The 10t sprocket allows you to achieve a desired gear ratio for good pulling power, recommend using at least a 60T drive sprocket. For larger tire application and extreme riding you will need a torque converter.

Note- No set screws available, must have crankshaft that is threaded for a bolt to hold clutch in place.

Not available for #35 chain

Dimensions:

Note- No set screws available, must have crankshaft that is threaded for a bolt to hold clutch in place.

Not available for #35 chain

Dimensions:

- Outside Diameter 4 3/4"

- Total Width 2 1/2"

- Clutch Back to Sprocket is 2"

US Dollar

US Dollar

Australia

Australia

Canada

Canada